- A power meter in microwave systems is essential for accurate, reliable power measurement at high frequencies.

- Microwave power meters directly measure RF and microwave power, making them more reliable than voltage-based methods.

- Accuracy affects system performance, safety, efficiency, and regulatory compliance.

- Different sensor types (thermal, diode, peak) suit different applications.

- Proper setup, calibration, and handling are critical to avoid measurement errors.

In high-frequency applications, accurate measurements are essential to every successful engineering system. In microwave and RF design, even minor measurement errors can lead to degraded performance, safety risks, and costly design mistakes. It is due to this reason that the power meter used in the microwave systems is such a critical factor in the laboratories, production floors, and field installations.

The microwave power meter is among the most reliable tools in the measurement of microwave activities, whether it is in validating the transmitter output or in terms of regulatory compliance. This article provides a professional explanation of the working mechanism of a power meter microwave system, the importance of accuracy, and how one of the engineers can get reliable results when using a power meter in the real world.

Understanding Power Measurement in Microwave Systems

Microwave systems typically operate at frequencies above 300 MHz and extend into the gigahertz (GHz) range. At such frequencies, low-frequency methods of measurement are no longer adequate. Changes in signal behavior, growth in losses and parasitic effects gain relevance.

A microwave power meter has been made to cope with these challenges. It quantifies the actual power of a microwave source, amplifier or transmitter and gives the engineer one straightforward and reliable parameter with which to assess the performance of the system.

Contrary to the measurement of voltages or currents, power is one of the most stable and repeatable quantities in high-frequency microwave systems, and the microwave power meter is a staple of RF test systems.

What Is a Microwave Power Meter?

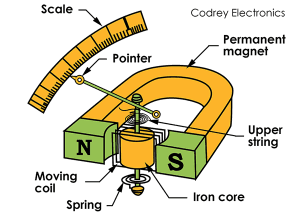

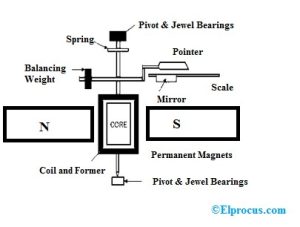

A microwave power meter is an instrument used to measure the average or peak power of microwave signals. It typically consists of two main parts:

- A power sensor, which interacts directly with the microwave signal

- A display or processing unit, which converts the sensor output into a readable power value

Depending on the design of the sensor, a power meter microwave system has the potential to measure power over a wide range of frequencies extending between a few megahertz and tens of gigahertz.

Since the measurement of power is independent of the shape of the waveform or complexity of the modulation of digital signals, the power meter of microwave systems is highly applicable both to simple continuous-wave (CW) signals and more complex digitally modulated signals.

Why Accurate Power Measurement Matters?

1. System Performance and Efficiency

In the microwave systems, coverage, signal quality, and efficiency are directly proportional to the output power. A faulty result of a microwave power meter can make engineers think that a system is working when it is not.

A power underestimation may lead to inadequate performance of the system whereas overestimation can cause system overheating, distortion or breaking of components. The correct power meter microwave system is important for accurate power measurements to ensure that amplifiers, transmitters and antennas are working according to their specifications.

2. Safety in High-Power Microwave Applications

High-power microwave systems are widely used in radar, satellite communication, and industrial heating applications. The wrong power values can be life-threatening to the equipment and human life.

A trustworthy power meter in a microwave system will assist avoid unnecessary overexposure, destruction of components and unsafe operation environments, as it will give assurance of measured power.

3. Compliance with Standards and Regulations

Several wireless and microwave networks are required to meet stringent regulatory restrictions on the power radiated. The government defines the maximum allowable power to prevent interference and allow safe operation.

It is necessary to show compliance by using a calibrated microwave power meter. Certification and approval processes can be considered to be unreliable and dangerous without proper power measurements.

Working Principle of a Power Meter in Microwave Systems

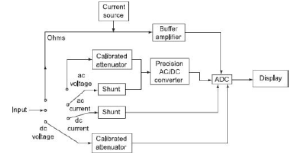

The working principle of a power meter within the microwave systems is grounded in the fact that the conversion of the high frequency microwave power energy into something that is measurable and traceable is done accurately. Microwave signals cannot be accurately measured using conventional voltmeters or ammeters, making direct power measurement essential at high frequencies.Rather, a microwave power meter is used to measure the actual power picked up by the microwave signal, and thus it is one of the most reliable measurements in RF and microwave engineering.

In this effort, a basic power meter microwave system will be composed of a power sensor and a display unit or a processing unit. They combine to convert the microwave energy to useful power readings, usually in the form of watts or dBm.

Basic Measurement Concept

- The microwave signal is applied to a power sensor

- The sensor absorbs part or all of the microwave energy

- This energy is converted into heat or an electrical signal

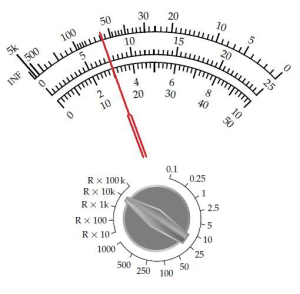

- The meter processes this signal and displays power in watts or dBm

Because the power meter in microwave systems measures actual energy rather than inferred values, it provides high accuracy across wide frequency ranges.

Types of Microwave Power Meters

Microwave systems are used with a high level of frequencies, power and signal formats. Different kinds of microwave power meter have been developed in order to cover these diverse needs. None of the types is universal, as each of them relies on a different principle of measurement and is designed to be applied in a particular application. Knowledge of these kinds can assist engineers to choose the appropriate power meter in the microwave systems so as to make precise and dependable measurements.

Thermal Power Meters

- Measure power by detecting heat generated by microwave energy

- Known for excellent accuracy and stability

- Ideal for calibration and reference measurements

Thermal sensors make the power meter microwave extremely reliable for average power measurements.

Diode Detector Power Meters

- Use semiconductor diodes to detect microwave signals

- Faster response time than thermal sensors

- Suitable for low-power and modulated signals

These sensors are widely used in modern power meters in microwave instruments due to their versatility.

Peak Power Meters

- Designed to capture fast, high-power pulses

- Essential for radar and pulsed microwave systems

- Measure peak, average, and pulse parameters

Components of a Microwave Power Measurement Setup

The power meter alone does not guarantee reliable microwave power measurement.Proper connection of the components and their selection are the keys to the right results. Every component of the system has a direct effect on the quality and consistency of measurements as well as their safety. To make good use of a power meter in microwave systems, it is important to understand these components.

A complete power meter microwave setup typically includes:

- Power sensor: The most critical component determining accuracy

- Meter or display unit: Processes and displays measured power

- Interconnects: Coaxial cables or waveguides for signal delivery

Every component affects the overall accuracy of the microwave power meter, making careful selection and handling essential.

Factors Affecting Accuracy in Microwave Power Measurement

Measurement of microwave power is very critical to assure proper performance, safety, and compliance with regulations of a system. Although a power meter of high quality appears in the microwave systems, there are a number of external and internal factors that may affect the accuracy of measurements. The knowledge of these considerations assists the engineers to reduce mistakes and to get reliable results of a microwave power meter.

Even the most precise microwave power meter can produce inaccurate results if key influencing factors are ignored.

a) Frequency Response

Sensors have specified frequency ranges. Using a sensor outside its rated band can introduce significant errors.

b) Mismatch and VSWR

Impedance mismatches between the source and sensor cause reflected power, reducing measurement accuracy. High-quality sensors are designed to minimize these effects.

c) Temperature Effects

Thermal drift can affect readings, especially in long-duration measurements. This is why stable environments and warm-up times are important for microwave power meter accuracy.

D) Calibration Uncertainty

Every power meter microwave system must be calibrated against traceable standards. Skipping calibration leads to unreliable data.

Applications of Microwave Power Meters

Microwave power meters are important tools where microwave and RF energy is produced, transmitted or measured. The power meter has become very common in microwave systems due to the repeatability and reliability of power which is one of the most reliable parameters at high frequencies. The following are the critical areas of application of a microwave power meter.

The power meter microwave is used across a wide range of industries:

Communication Systems

- Cellular base stations

- Satellite uplinks and downlinks

- Microwave backhaul systems

Radar and Defense

- Transmitter power validation

- Pulse power measurement

- System diagnostics

Research and Education

- University laboratories

- Microwave component characterization

- Experimental RF systems

Manufacturing and Production Testing

- Quality assurance

- End-of-line testing

- Compliance verification

In all these cases, the power meter in microwave systems ensures repeatability, reliability, and confidence in results.

Common Mistakes to Avoid When Using a Microwave Power Meter

A high-quality instrument may not give the correct result despite the instrument being of high quality unless the appropriate measurement practices are applied. The microwave power meter is not the cause of many of the errors in microwave testing, but improper setup, poor handling, or lack of understanding of the measurement limits. To a great extent, preventing the following widespread errors will help to enhance the accuracy, safety, and reliability of any power meter in microwave systems.

Even experienced engineers can encounter errors when using a microwave power meter:

- Selecting the wrong sensor for frequency or power level

- Ignoring cable and connector losses

- Overloading the sensor

- Skipping warm-up and zeroing procedures

Avoiding these mistakes significantly improves the reliability of power meter microwave measurements.

Conclusion

Precision in power measurement is not only a technical specification, but a base of performance in microwave engineering, safety and compliance.Microwave systems rely on power meters to provide a direct, reliable, and trusted method for gauging microwave signal power. in industries and applications.

With the knowledge on how a microwave power meter operates, the factors influencing its precision and the proper use of the meter, engineers are able to know that their systems are functioning as they expected. The power meter microwave has also been one of the most critical equipment in the modern RF and microwave measurement, in a field where precision is a critical factor.

Frequently Asked Questions (FAQs)

- What is a power meter in microwave systems?

A power meter in microwave systems is an instrument used to measure the actual power of microwave and RF signals accurately, typically in watts or dBm. - Why is a microwave power meter preferred over voltage measurements?

At microwave frequencies, voltage and current are difficult to measure directly. A microwave power meter provides stable, direct, and repeatable power measurements independent of waveform shape. - What types of microwave power meters are commonly used?

Common types include thermal power meters, diode detector power meters, and peak power meters, each designed for specific power levels and signal types. - What affects the accuracy of a power meter microwave measurement?

Accuracy is influenced by sensor frequency range, calibration, mismatch (VSWR), cable losses, temperature, and proper sensor selection. - Where are microwave power meters used?

Microwave power meters are widely used in wireless communication, radar, satellite systems, R&D labs, manufacturing, aerospace, and educational institutions.